-40%

ZIR X DENTAL ZIRCONIA CROWNS BLANK CAD CAM MILLING MACHINE BLOCK OD 98* 12 ST

$ 46.18

- Description

- Size Guide

Description

ZIR XZIR-X is a circular shaped block made up of Zirconia and Ceramic. It consist of high strength, excellent permeability, low thermal conductivity, and color aesthetic repair effect that is suitable for CAD/CAM system and manual system.

COMPOSITIONS:

ZrO2(zirconium dioxide) + HfO2(Hafnium dioxide)+ Y2O3(Yttrium oxide) ≥ 99%

Y2O3:4.5%;~6.0%

Al2O3(Aluminum oxide) ≤ 0.2%

Other Oxides ≤0.4%

ADVANTAGES

Can be easily modified, reshaped and recolored.

Resemble natural tooth enamel due to their color and translucence.

Do not require a metal base.

Do not require as much of the original tooth be removed as with other types of crowns.

No irritation.

Good Bio-Compatibility.

Resist staining better than acrylic or composite ceramic crowns.

Low thermal conductivity.

Hot and cold changes do not stimulate the pulp.

Extremely Durable

FABRICATION OF ZIR-X

ZIR-X are available in narrow size blocks sent to laboratories.

It is milled into single unit copings or multiple- unit fixed bridge frameworks.

INDICATION

BRIDGE RESTORATION – Used from single tooth crown to 14 units bridges.

Features

A natural white color.

High hardness.

High Fracture toughness (Zirconia is difficult to crack).

Resistance to wear.

Translucent appearance when sintered (Baked)

Key Specifications

Durability

Over 1000 MPa Perturbed strength

Packaging

Pack of 1 Block

Direction to Use

The Burn out Oven and Casting machine have been replaced by “Model Scanning” and CAD / CAM milling machines.

Keyboard, Monitors and cursors are used instead of wax , Bunsen Burner and Carvers to Fabricate the crown Bridge work.

ZIR_X are Fabricated by CAD/CAM SYSTEM

1.COMPUTER-AIDED DESIGN/COMPUTER-AIDED MANUFACTURING (Cad/Cam) METHOD.

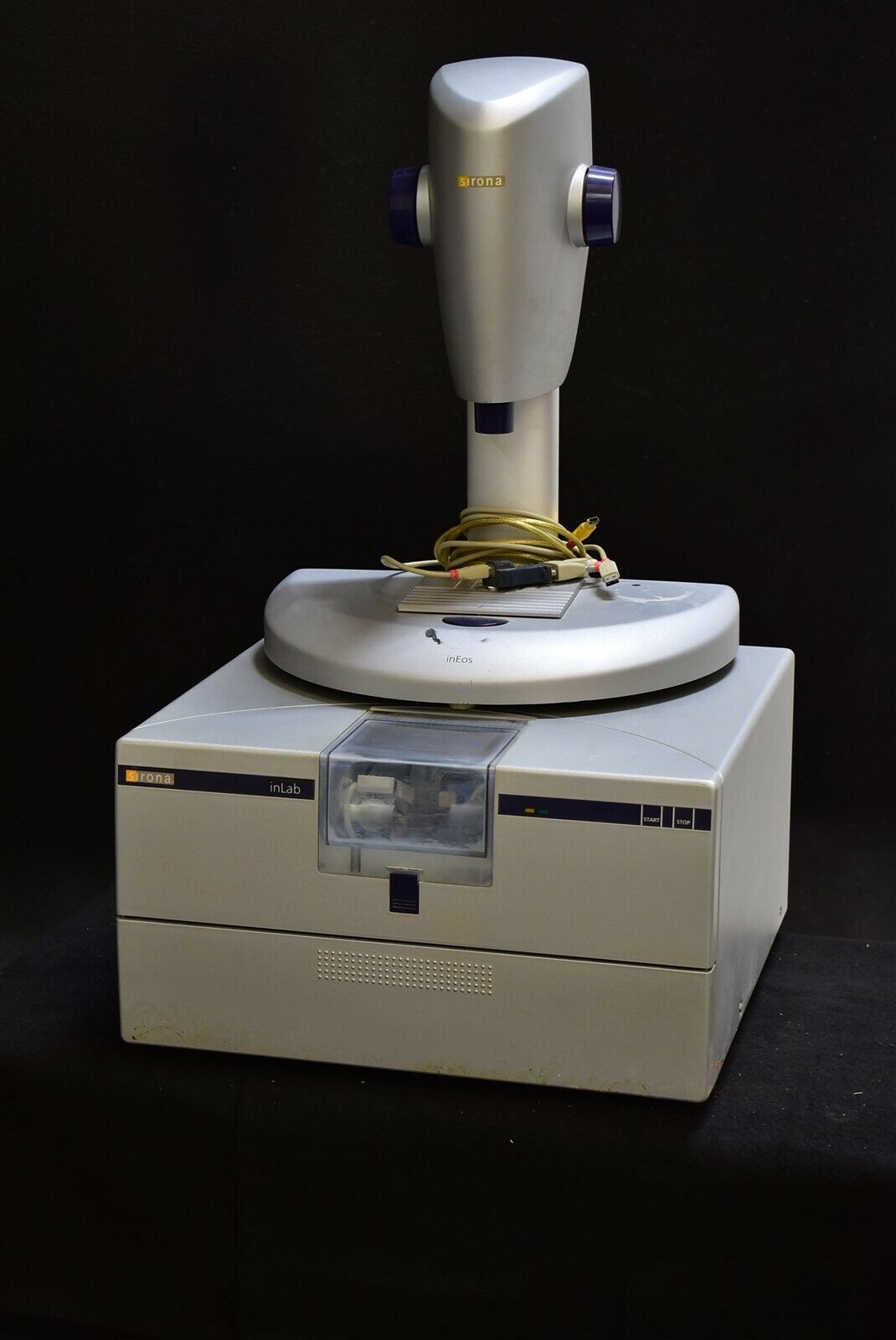

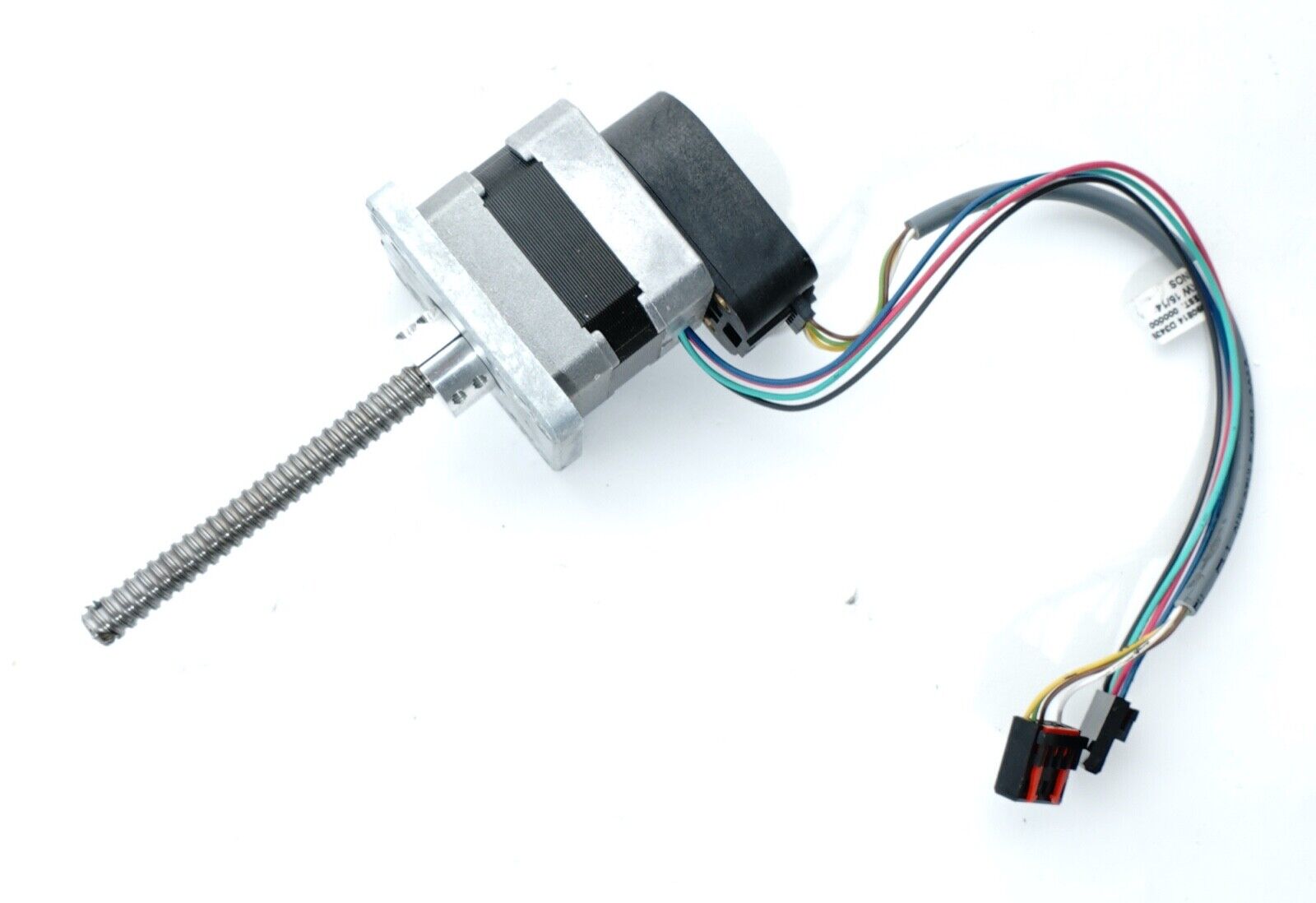

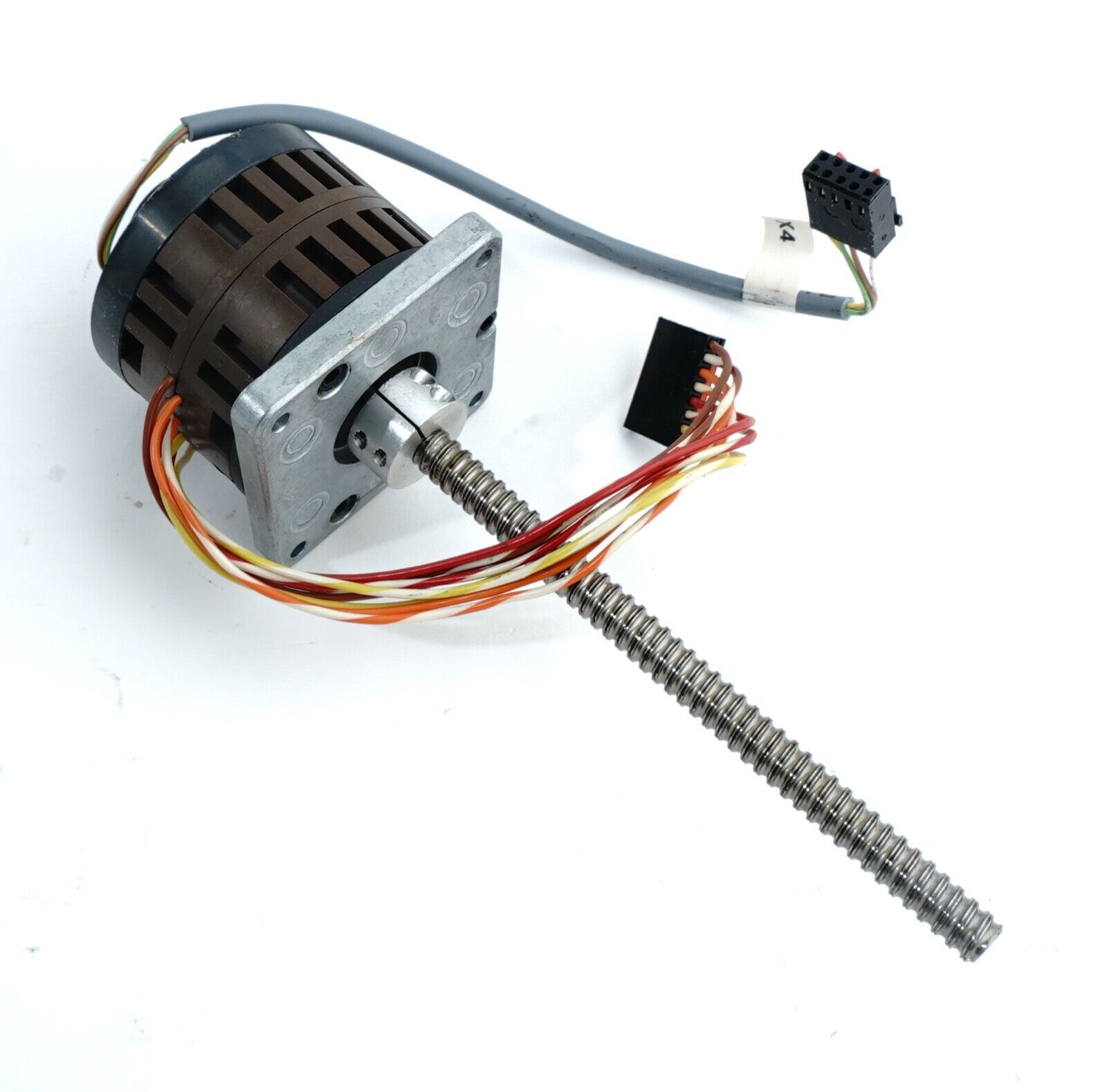

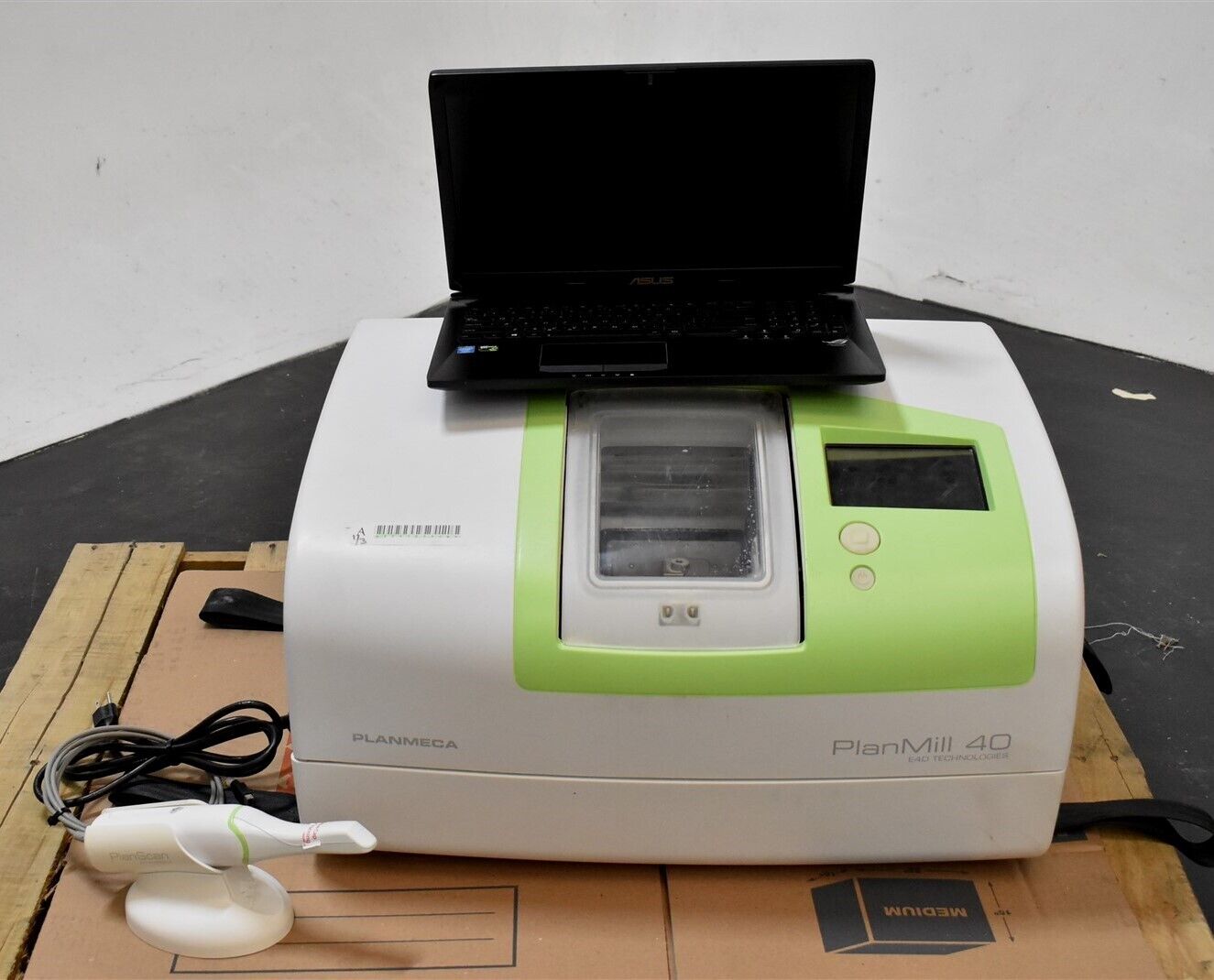

This method of fabricating zirconia single copings and frameworks involves the manipulation of a 3-D design on the computer screen, followed by the automated production by a computer-controlled milling machine. There are three components to the CAD/CAM system: scanning, designing, and milling. All are usually housed at the laboratory.

2. MANUFACTURER -SPECIFIC CLOSED SYSTEM

The method of fabrication used by dental laboratories is scanning the tooth-prepared models, designing the single coping or framework using a particular company’s construction software, and then electronically sending the information to the company’s milling center. This is usually a closed system, which means the scan and design data can only be used at that particular manufacturer’s milling center

The sale of this product/item may be subject to regulation/ jurisdiction administration and state and local regulatory agencies.

If so not to bid on or buy this product/item unless you are an authorized purchaser.

I will/ may verify your status as an authorized purchaser of this item before shipping of the product/ item.

·

We accept all the credit/debit cards for payments through

P

ay

P

al

only.

·

We take all returns of the products as per eBay rules and regulations.

Note:- Company may change the packing of the products time to time, But we will ship only the latest packing available at time of sh

ipping.

The sale of this item may be subject to regulation by the U.S. Food and Drug Administration and state and local regulatory agencies. If so, do not bid on this item unless you are an authorised purchaser. If the item is subject to FDA regulation, I will verify your status as an authorized purchaser of this item before shipping of the item.

IMPORT DUTIES, TAXES, AND CHARGES ARE NOT INCLUDED IN THE ITEM PRICE OR SHIPPING COST. THESE CHARGE

S ARE THE BUYER'S RESPONSIBILITY.

SATISFACTION GUARANTEED

FEEDBACK

Your feedback is important for us to grow our business on eBay, so please do not forget to leave your feedback.

Please give us strong positive rating if you like our product and service

We try our best to give our customers best services

If you find an issue with the product or have any concerns please don't hesitate to contact us

We will resolve the issue in a positive way

Higher customer satisfaction motivate us to do better things in a better way also helps other customers to make decisions about our product and service

.

.

.